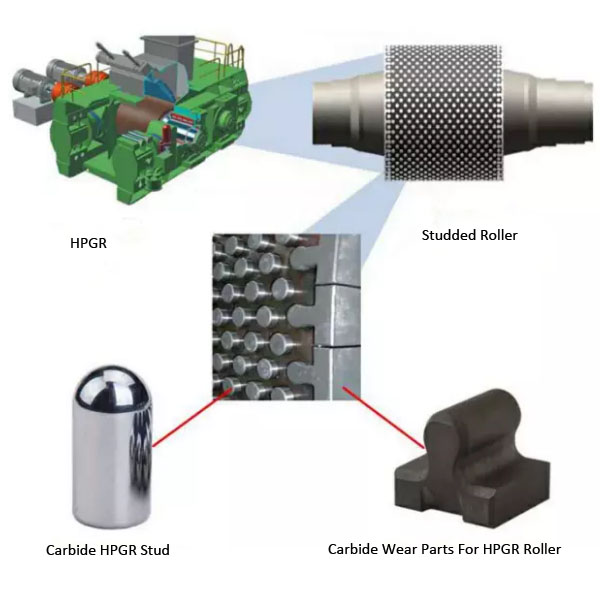

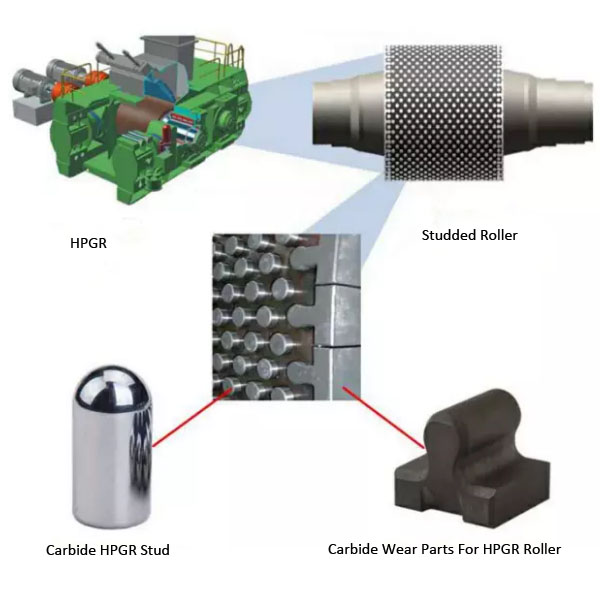

HPGR Tungsten Carbide Studs Used in Grinding Limestone

Material grade for HPGR tungsten carbide studs:

| Grade |

HRA |

TRS |

Density g/cm3 |

| YG11C |

≥ 86.5 |

≥2500 |

14.10 - 14.5 |

| YG13 |

≥ 85.5 |

≥2350 |

13.89 - 14.11 |

| YG15C |

≥ 85.7 |

≥2800 |

13.90 - 14.10 |

The above grades are all unique grades suitable for HPGR carbide studs. They have good wear resistance and compressive strength. HPGR roller suitable for crushing various kinds of rock such as cement and metal ore. Metal raw materials use HPGR roller for crushing are: Clinker, iron ore, Limestone, quartz stone and others metals with high efficiency operations.

HPGR Tungsten carbide studs features:

1. The ball crown with a hemispherical design would help avoid stress concentration and damage the steel body.

2. The corners with circular arc transition to avoid local damage during production, transportation, installation and usage.

3. All HPGR studs are sintered in pressure furnace, which has good density and high strength.

4. All HPGR studs through a special process, the surface stress of the studs are eliminated, while hardness increased.

5. The surface of the studs coated with a layer of grease to avoid oxidation.

The service life of carbide HPGR studs can reach more than 25,000 hours in cement raw materials, clinker up to 30,000 hours, and iron ore 8000~10000 hours.

Sizes of tungsten carbide HPGR sutds ( mm ):

| Diameter |

Height |

Dome |

Chamfer E×R |

| 20 |

40 |

SR10 |

2×R5.0 |

| 20 |

30 |

SR10 |

2×R5.0 |

| 20 |

35 |

SR10 |

2×R5.0 |

| 16 |

55 |

SR8 |

R2.0 |

| 16 |

50 |

SR8 |

R2.0 |

| 16 |

45 |

SR8 |

2×R5.0 |

| 16 |

40 |

SR8 |

2×R5.0 |

| 16 |

40 |

SR8 |

1×R2.0 |

| 16 |

40 |

SR8 |

1×45° |

| 16 |

35 |

SR8 |

R2.0 |

| 16 |

20.5 |

SR8 |

R2.0 |

| 10 |

22 |

SR5 |

R1.0 |

| 10 |

22 |

SR5 |

R1.5 |

| 10 |

20 |

SR5 |

R1.5 |

| 8 |

20 |

SR4 |

R1.0 |

Tungsten carbide HPGR studs has many sizes and types. like dome type, flat type...

Tungsten carbide HPGR studs has many sizes and types. like dome type, flat type...

They are a bit like tungsten carbide button.

but HGPR studs uaually have a high height, and require high hardness to insure abrasive.

Other sizes and shape could made under your drawing.

Photos of tungsten carbide studs used on HPGR Roller:

Tungsten carbide HPGR studs has many sizes and types. like dome type, flat type...

Tungsten carbide HPGR studs has many sizes and types. like dome type, flat type...